This would be our last practical. We did experiment on the effect of fat content and fat replacer in cookies.

The objective of this experiments are:

1. To evaluate the effects of emulsifier & fat-replacer in cookies.

2. To evaluate the palatability, nutritive value of reduced-fat cookies.

Fats and oils are utilized for a range of products in the consumer market including cookies. Cookies are traditionally high-fat food products that acquire texture and flavor characteristics from fat (Malovany, 1995; Adair et al., 2001). Fat is very important ingredient of cookies, especially soft cookies which contain large amounts of fat. Fat contribute texture and pleasing mouth-feel and positively impacts flavor intensity and perception.

Several studies have reduced fat content of cookies due to health issue which concerned by most consumers. However, decreasing the amount of added fat had a great impact on textural attributes of cookies and produced less acceptable than high-fat cookies and with differences in flavor and texture more pronounced as the level of fat replacement increased (Adair, 2001). According to Sanchez and friends (1995), reduction of fat in cookies resulted in a chewy texture and a low moisture content.

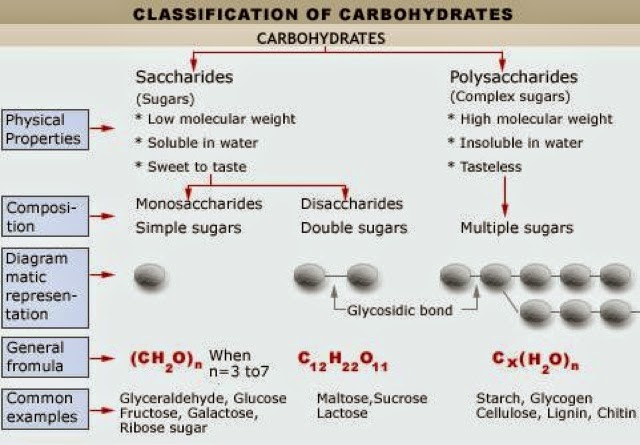

Fat in cookies and similar baked products can be replaced by carbohydrate or protein origin.

Carbohydrate-based fat mimetics like processed starches imitate fat by binding water and to provide lubricity, body and a pleasing mouth sensation (Bath et al, 1992). Conforti and friends (1996) reported that tenderness of biscuits decreased with the increase of fat substitution by pectin-, gum- or oat-based fat mimetics.